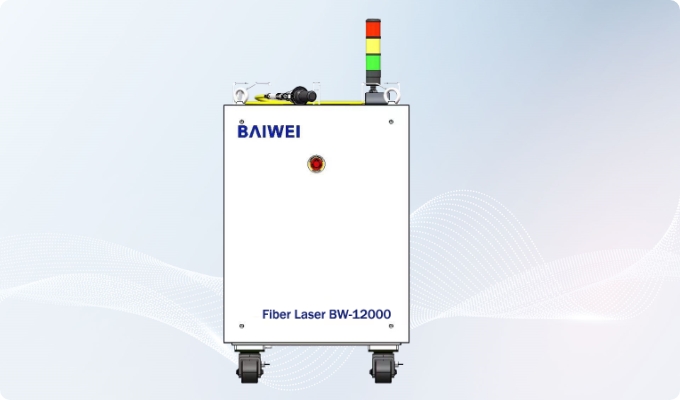

BW high-power laser source is a first-line laser generator manufacturer in China, and one of the world's leading developers and manufacturers of high-performance fiber laser source. Our products involve many applications and markets. Main features: High electro-optical conversion efficiency; high output power, superior beam quality; high power stability, high reliability, long life; all-fiber structure, compact structure, maintenance-free, and low cost.

The difference between Bescut's customized laser head (bescut) and other brands of laser heads is that other laser heads use collimating lenses, while we use collimating lens groups.

The most outstanding feature of the collimating lens group is that it can change the shape of "light" that the collimating lens does not have, so that the work efficiency can be further improved.

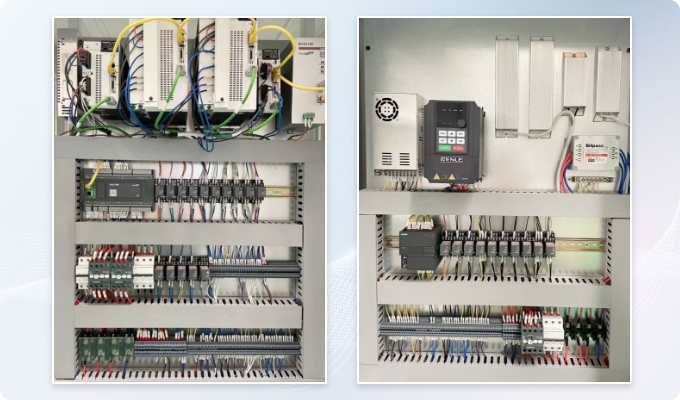

High performance, high efficiency, intelligence and integration;

Plate cutting software cypcut;

Standard industrial computer, easy to operate;

Comprehensive diagnostic functions to quickly find faults.

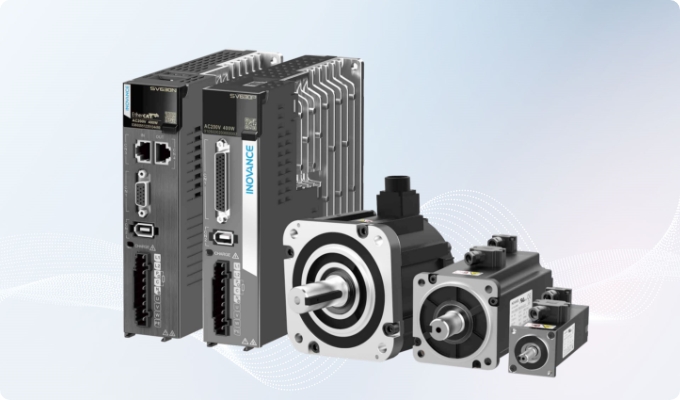

By parameter setting, deceleration and stop using the dynamic brake that short-circuits the servo motor power line can be selected when any service is OFF or an alarm occurs. The deceleration can be effectively performed when the power supply of the vertical conveyance control is OFF, the servo is OFF, or an alarm occurs.

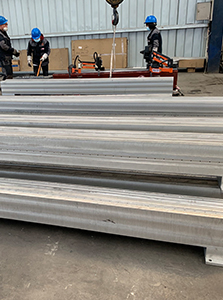

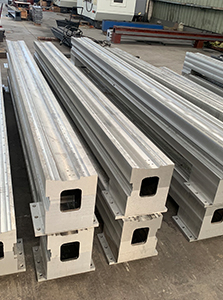

The HG series linear guide is a four-row single-arc tooth contact linear guide. At the same time, it integrates the heavy-duty precision linear guide with optimized structural design, which improves the load and rigidity; it has four-way load characteristics and automatic centering function. , can absorb the assembly error of the mounting surface, and obtain high-precision requirements.

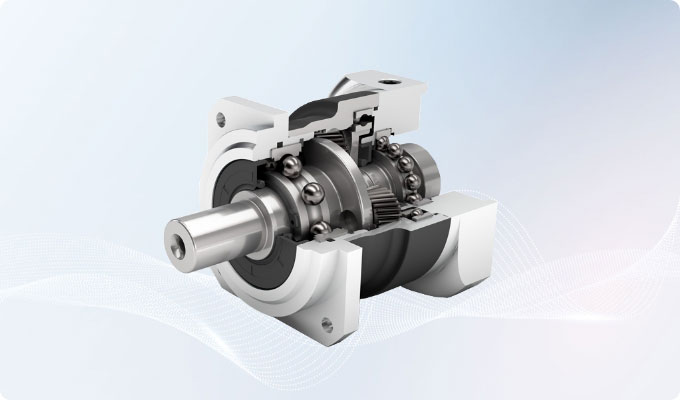

High precision, long life, can provide rigoroussupportfor quenching helical gears and grindinghelical gears,so that the load drive structure is compact, caneffectively reduce the driving torque.

Perfectly connected architecture, high-speed deployment;

Security visualization, efficient operation and maintenance;

Data acquisition and transmission, breaking and closing control.

Our PSN embodies pure progress: Its innovative helical teeth safeguard low-noise operations. This precision planetary gearbox minimizes vibrations, and therefore increases the quality of your workpiece surfaces even under the highest bearing loads.Our PSBN is the ideal combination of precision planetary gearbox and efficient bearing technology. It has been developed specifically for delivering the maximum performance at high speeds. Its helical teeth provide homogeneous synchronism and quiet running noise. Ratios: 3-100

1. Specially developed for fiber laser equipment, compatible with all brands of lasers (easy to choose).

2. Environmentally friendly refrigerant, no worries about export.

3. Comprehensive testing by professional laboratories.

4. Stable and reliable performance, low failure rate, energy saving and power saving.

5. High efficiency and environmental protection

6. Dual temperature and dual control

7. Flow and over-temperature alarm.

8. Press thermal protection.

9. Phase sequence protection.

10. Leakage protection.